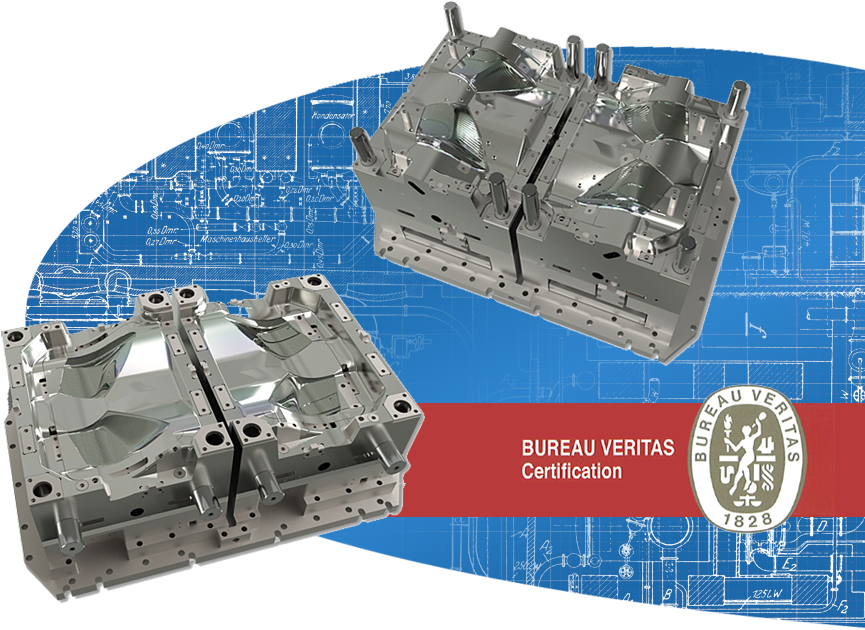

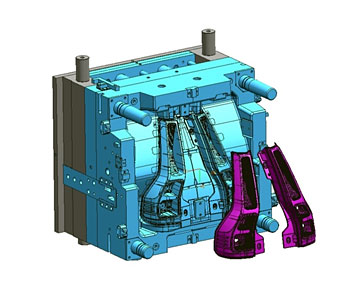

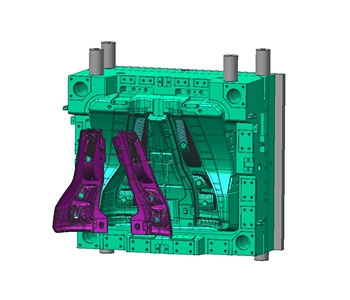

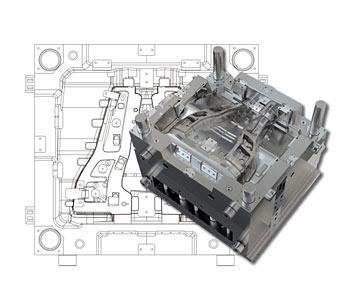

Mold Ability

High Quality Product Is From High Quality Mold

Injection Molds

BMC Molds

Insert moulding Molds

Multi-Color / Multi-Material Molds (2K / 3K molding)

Mold capacity : 50T-1600T ( Injection molding )

Project management

On Time Delivery

Rigorous mold standard to meet or even exceed customer expection

Clear communication and weekly scheduling reports

From concept to final product, complete project management supported

Tool Design & Mold flow

Provide CAD / tooling feasibility pre-study service to customer.

Complete mold flow analysis and optimization of mold structure to save development time & cost.

More than 3000 sets mold design experience, rigorous mold design specifications to ensure mold life and production stability.

Ensure mold spec to suit within customer's production machine.

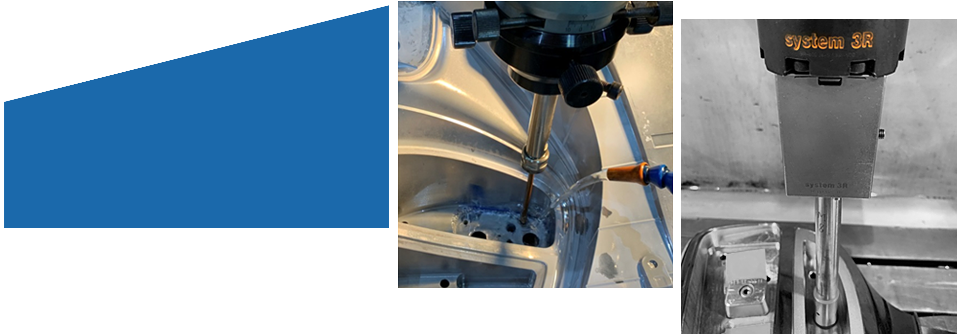

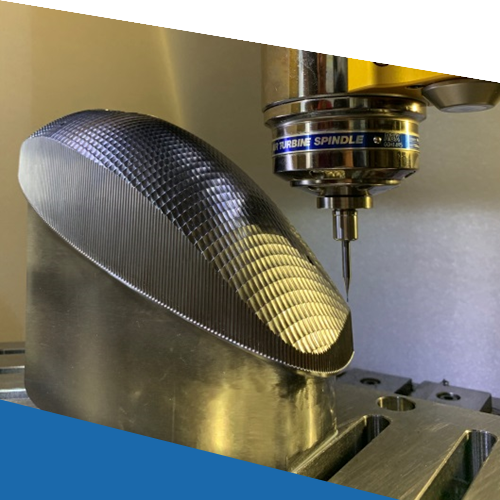

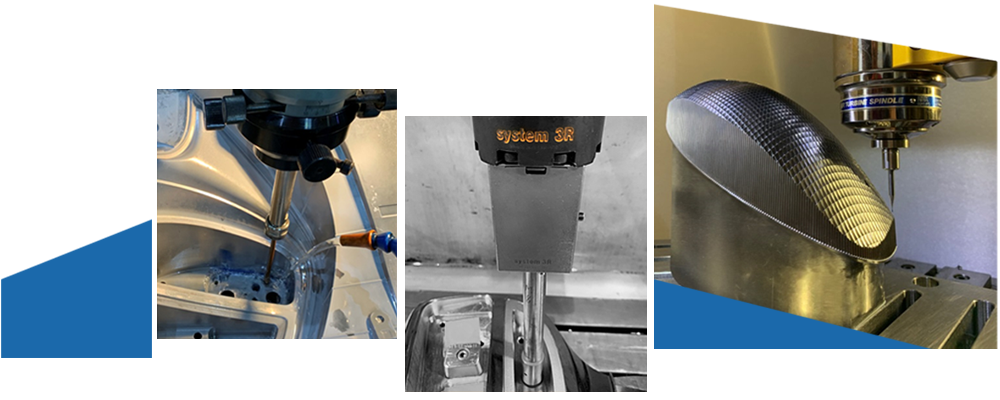

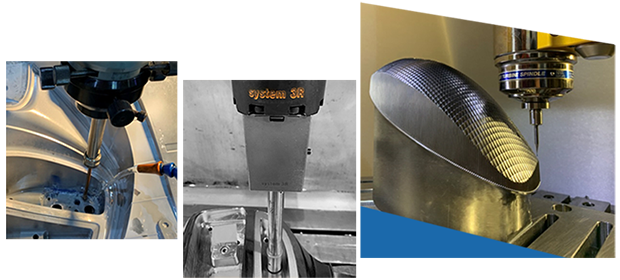

Machining

8 CNC machines, machine capacity to 2 meter molds (1600T)

Rough to fine surface cutting by different exclusive machine to achieve superior surface finishes.

Exclusive high speed machining facility for LED optical surface.

Skilled CNC & EDM machining process to minimize hand work and need for polishing.

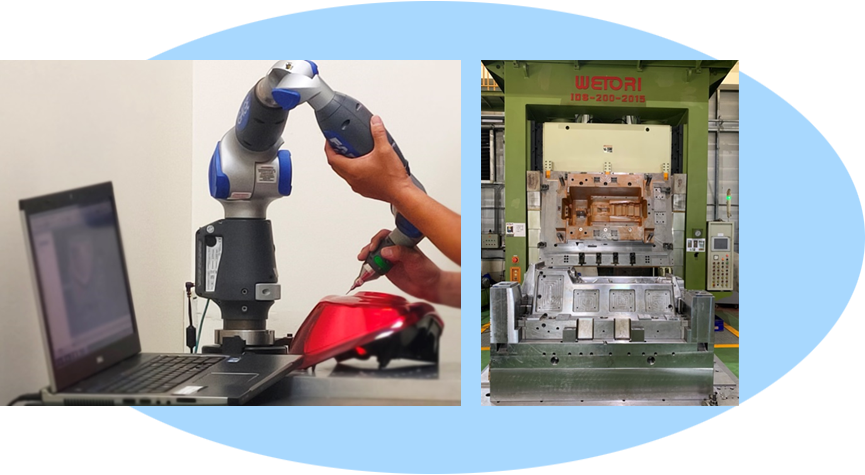

Ability & Quality Verification

Vertical integration system (design, mold and production) , single window provide clear information and take fully responsibility to ensure product sucess.

In house facility for 2K/3K mold manufacturing and quick molding verification, accumulated lot of development knowledge to save developing time and cost for customer.

Performs tests and validation procedures are done for all new moulds to ensure molds are ready for serial production.